Equipment

Equipments

QUALITY POLICY:

The object of Quality Assurance is to ensure optimum standards and fail-proof workmanship for client satisfaction.

Our Internal Quality Control (IQC) team experts direct control at stage of manufacture and process right from raw material stage process to final product Inspection. The team monitors and maintains document-recording, history of material.

At all stages of manufacturing, a wide variety of certified measuring and checking devices are utilized to assure conformance to all applicable quality standard. A final inspection is made after all forging scale has been mechanically removed prior to painting.

Progressive inspections assure that our product meet all applicable standards & code.

The accurate bevelling at the end facilitates sound weld. The square & straight face permits perfect alignment with pipe.

INTER-TECH FITTINGS INDIA PVT. LTD. is committed for quality & timely delivery of its products to customer at competitive prices & continually improve the performance.

We will achieve this by:

- Planning & Segmenting our Market.

- By applying world-class technology in our production.

- By motivating & training our employees.

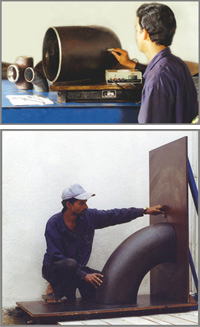

PRODUCTION FACILITY & MANUFACTURING PROCESS:

Keeping pace with changing demands of the industries we serve, we try to bring out the production with most modern Technology available. The Elbows & Bends we make in the above Mandrel Machine are of the best Quality available with the optimum rate of production.

We have all in house facilities for manufacturing of Pipe Fittings and Long Bends such as Cutting, Hot & Cold Forming, Bending, Pressing, Ball Passing, Welding, Grinding, Finishing, Handling, Heat Treatment, Temperature controlling with Heat Treatment Chart for Client review.

Machining, Drilling, Surface Treatment like Short Blasting, Sand Blasting, Pickling, and Antirust Coating is provided before despatch of Material.

N.D.T. and Dimension checks are carried out with calibrated Gauges & Instruments like Hardness Testing Machine, Ultrasonic Digital Thickness Checking Machine, D.P. Test Set, PMI, GALVANISING COATING and various types of fixtures.

Our Quality Assurance Plan, WPS, PQR is approved and accepted by various 3rd Party Inspection Agencies.

Typical applications :

Our butt weld fittings can be employed in many varied applications, some of these are listed as follows.

- Cold water

- Hot water

- Steam generation

- Industrial generation

- Industrial gases

- Chemical and petrochemical plants

- Oil and gas - including production, transportation, compression and refrigeration plants, refining, distribution, terminal construction.

- Offshore exploration and production platforms

- Furnace building

- Ship building

- Food industry equipment